|

||||||

Well Testing & Diagnostic Services This division caters to the optimization requirements of the upstream production capability of AL MANHAL clients in the region. We own state-of-the-art equipment for surface production well testing, well weighing and diagnostic services, which are operated by a team of highly skilled and experienced professionals. |

Well Testing Services |

|

Diagnostic Services |

|

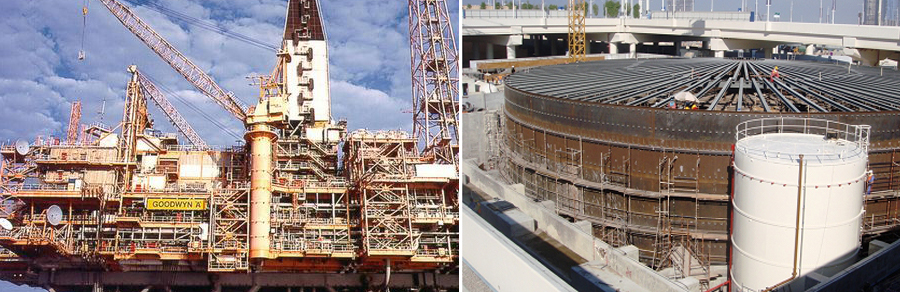

Industrial Process Piping With a workshop area of approx. 52500 m2, AL MANHAL's fabrication & welding division deals with structural steel, miscellaneous metal, plate work fabrication for industrial, institutional and commercial projects. We work hand in hand with your project team to contribute to the winning environment that you strive to create on your project. Today AL MANHAL offers a variety of custom made products to its industrial clients such as but not limited to the following: We have a fully equipped fabrication facility complete with modern equipment, Qualified Welders, Pipe Fitters/ fabricators, structure steel fabrication equipment, and 24 shift capacities. We do both carbon steel & stainless steel fabrication, with full QA traceability, as required. |

|

Fuel System Design, Installation, Testing & Training. We undertake Bulk Fuel Storage Tank, Day Tank, Fuel Automation & Management system design, installation & training as per API standards.

|

|

Lubricants Distributer RS CLARE - The leader in Gate valve lubricants. Distributer for RS Clare special made lubricants can offer a full service from product concept design to manufacture. RS Clare manufactures a full range of standard and high performance greases for specialist applications.

|

|